Post by thirdgen60 on Oct 24, 2011 16:21:00 GMT -6

So decided to get an early start on my winter project. Originally i was planning to build a shortblock this winter but if i did that then i wouldn't have the money for the turbo build until the summer. And who wants to drive around on a low compression built motor with no power adder???

I spent most of Saturday building a set of log manifolds. I decided to build the log manifolds mostly because i didn't like the way any of the stock manifolds fit. I enjoy the fabrication and this way they will fit exactly the way i want them to. I hope you guys like pictures!

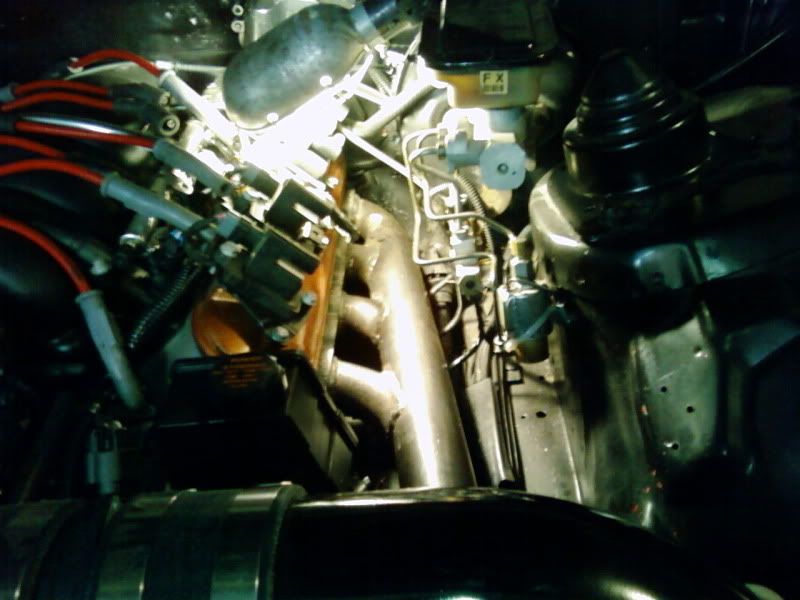

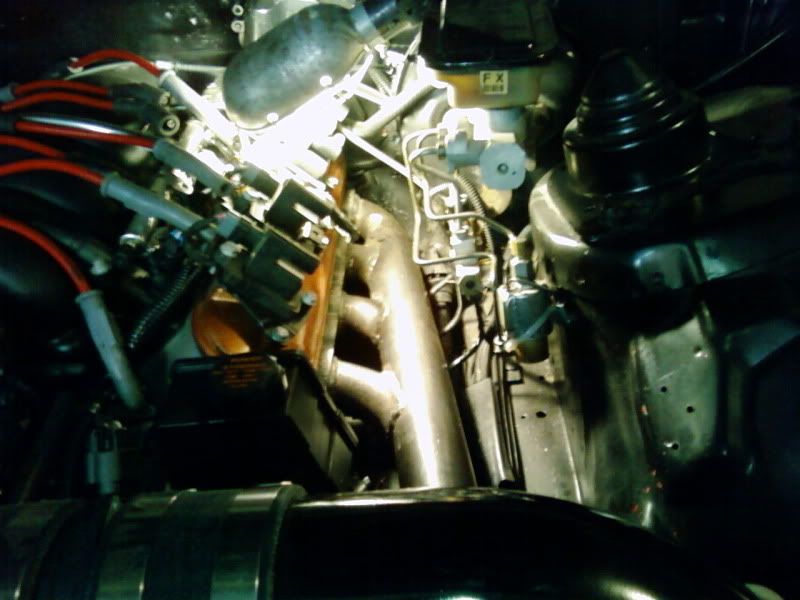

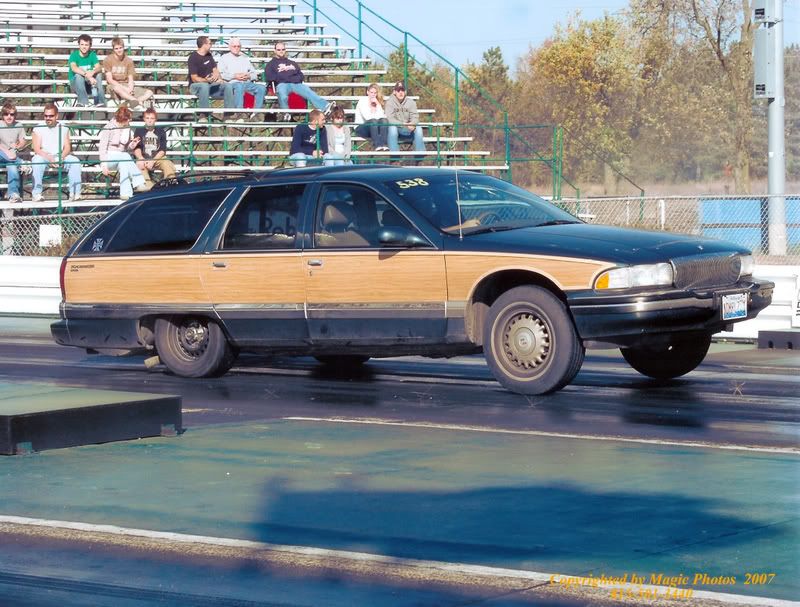

Most of you probably know my car by now but for those that dont my current setup that im am working off of is an LQ4 with L92 heads, backed by a 4L80E. Here is a pic.

I should start by saying the primaries are 1 7/8in and the log portion is 2 1/4in. After pulling both headers off the car i got started by necking down the passenger side log and welding to the rear primary. Also the tubing i am using has a fairly thick wall, i did this because this car gets a lot of miles put on it and i wanted to avoid any chance of cracking.

I then tacked that up to the flange in the desired position.

Next i very painstakingly cut out the next primary with my sawzall and grinder. Since it took about 45 min to get it just right, i knew i needed a better way to make the primaries. Thats when i had a stroke of genius.... Duct Tape!!

The duct tape mold along with a friends plasma cutter were then used to very easily make exact duplicates for the other 2 primaries on this side.

Bolted it up to a mock up head and finished up the welding.

I used the same principles to make the drivers side manifold.

I made each of the duct tape molds by lubricating the tubing i was using, wrapping with duct tape, sticky side out, then wrap again the normal direction, and slide it off

Slid it in and marked where it needed to be cut

After trimming

Some shots with both all welded up and on the car. Both manifold will be cut shorter and have v-bands welded on also. Im also undecided if i want to grind all the welds down or just leave them.

Just to get an idea of the turbo location.

I spent most of Saturday building a set of log manifolds. I decided to build the log manifolds mostly because i didn't like the way any of the stock manifolds fit. I enjoy the fabrication and this way they will fit exactly the way i want them to. I hope you guys like pictures!

Most of you probably know my car by now but for those that dont my current setup that im am working off of is an LQ4 with L92 heads, backed by a 4L80E. Here is a pic.

I should start by saying the primaries are 1 7/8in and the log portion is 2 1/4in. After pulling both headers off the car i got started by necking down the passenger side log and welding to the rear primary. Also the tubing i am using has a fairly thick wall, i did this because this car gets a lot of miles put on it and i wanted to avoid any chance of cracking.

I then tacked that up to the flange in the desired position.

Next i very painstakingly cut out the next primary with my sawzall and grinder. Since it took about 45 min to get it just right, i knew i needed a better way to make the primaries. Thats when i had a stroke of genius.... Duct Tape!!

The duct tape mold along with a friends plasma cutter were then used to very easily make exact duplicates for the other 2 primaries on this side.

Bolted it up to a mock up head and finished up the welding.

I used the same principles to make the drivers side manifold.

I made each of the duct tape molds by lubricating the tubing i was using, wrapping with duct tape, sticky side out, then wrap again the normal direction, and slide it off

Slid it in and marked where it needed to be cut

After trimming

Some shots with both all welded up and on the car. Both manifold will be cut shorter and have v-bands welded on also. Im also undecided if i want to grind all the welds down or just leave them.

Just to get an idea of the turbo location.

..... I know its from China because when i took the end cap off the first time it smelled like harbor freight inside ;D

..... I know its from China because when i took the end cap off the first time it smelled like harbor freight inside ;D